Exploring the cross-border applications of glycerol monooleate(GMO)

Release time:

2025-09-02 11:28

Source:

What is glycerol monooleate?

Behind food, cosmetics, medicine and even plastic products lies a low-key "all-rounder" - glycerol monooleate. As an outstanding representative of green chemistry, this compound derived from natural oils is quietly changing the landscape of modern industry.

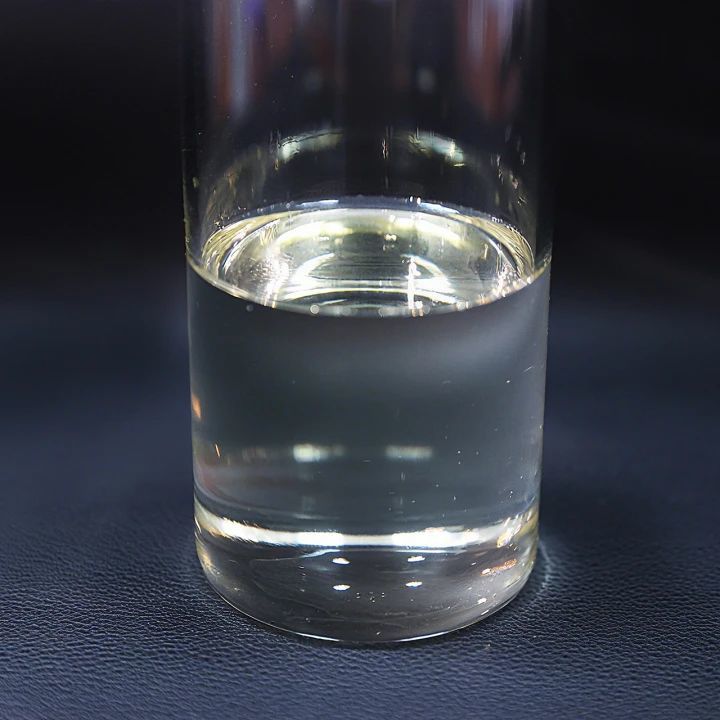

According to the different contents of total monoglycerol fatty acid esters and free glycerol, it is generally divided into GMO40 and GMO90 on the market. It appears as a milky white or light yellow liquid or paste, with an HLB value of 3.5-4.0. It is easily soluble in oils and can be dispersed in water. From a chemical perspective, its molecule is composed of three elements: carbon, hydrogen, and oxygen. Carbon forms the basic framework of the molecule, hydrogen endows the molecule with appropriate flexibility and hydrophobicity, and oxygen tightly connects glycerol and oleic acid through ester bonds. This unique structure endows glyceryl monooleate with both hydrophilicity and lipophilicity, which is precisely the secret behind its ability to be an excellent emulsifier.

It is reassuring that the safety of glycerol monooleate has been recognized by global authoritative institutions. The US FDA has included it in the GRAS list. The Cosmetic Ingredient Review (CIR) expert panel has also confirmed its safety for use in cosmetics. Moreover, the Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO) has not set a limit on its daily intake.

At present, there are mainly three production methods in the industry, including traditional esterification method, enzymatic catalysis method and supercritical fluid method. Cardlo has achieved a technological breakthrough in this field. The "Large-scale Continuous Green Manufacturing Technology for High-Purity Fatty Acid Glycerides" developed in collaboration with universities such as Jinan University and South China University of Technology has reached the international leading level. This technology adopts a solvent-free/green solvent system, achieving zero discharge of wastewater, waste gas and waste materials, and saving about 20% of energy consumption compared with traditional processes. Through a four-stage molecular distillation purification process, the purity of glycerol monooleate has been further increased from 99.2% to over 99.8%.

| Item | GMO40 | GMO90 |

| Appearance | Light yellow or milky white liquid or paste | Light yellow or milky white paste |

Total monoglycerol fatty acid esters(w/%) | ≥35.0 | ≥90.0 |

Acid value(mg KOH/g) | ≤6.0 | ≤6.0 |

Free glycerol(w/%) | ≤10.0 | ≤7.0 |

Saponin (calculated as sodium oleate)(w/%) | ≤6.0 | ≤6.0 |

Moisture(w/%) | ≤2.0 | ≤2.0 |

Lead (Pb)(mg/kg) | ≤2.0 | ≤2.0 |

Glycerol monooleate: A versatile player in cross-border applications

Glycerol monooleate has shone brightly in many fields due to its excellent emulsifying, stabilizing and thickening properties.

The food industry is its most important application scenario. Glycerol monooleate comprehensively improves the texture, freshness and processing performance of food through four mechanisms: interfacial emulsification, starch complexation, crystallization regulation and foam stabilization, while also having health properties (containing essential fatty acids linoleic acid/alpha-linolenic acid). The main functions are reflected in: emulsification effect, stabilizing the oil-water interface; Anti-starch aging and delay food hardening; Regulate oil crystallization and optimize texture stability; Foam stabilization and functional enhancement.

In the cosmetics industry, glyceryl monoleate, as an emulsifier and emollient, is widely used in products such as face creams, lotions, and lipsticks. It can help the oil and water components mix evenly, improve product stability, and at the same time provide a smooth touch when in use. Its excellent skin compatibility has been verified through multiple safety tests.

In the medical field, it can be used as a drug carrier or solubilizer to enhance the bioavailability and efficacy of drugs, and is often employed in the preparation of creams, ointments and other preparations.

In terms of industrial applications, glycerol monooleate is used as a fabric finishing agent in the textile industry, as an internal antistatic agent in plastic processing, and can also be used as a pigment grinding additive, etc.

Several core advantages of the monooleic acid glycerides produced by Cardlo

The technical strength is top-notch. As a key "Little giant" enterprise specializing in niche market innovation at the national level, Cardlo has been deeply engaged in ester materials for 20 years. It has established a national green factory, a Guangdong Provincial Engineering Technology Research Center, and a postdoctoral innovation practice base. It has successively won awards and honors such as the "25th China Patent Excellence Award" and the "First Prize of Guangdong Provincial Science and Technology Progress Award".

The product quality is excellent. Through the independently developed curved plate distillation equipment, heat exchange system, vacuum system and online monitoring system, a stable control of product purity of over 99.8% has been achieved, which is far higher than the industry average.

The concept of green production is practiced. Adopting a solvent-free/green solvent system efficient preparation process, it achieves zero discharge of wastewater, waste gas and waste materials, saving about 20% of energy consumption compared with traditional processes, truly realizing environmentally friendly and sustainable production. In 2024, it was rated as a "National Green Factory" by the Ministry of Industry and Information Technology.

Leading in production capacity scale. Build the world's largest single-line capacity (100,000 tons per year) intelligent and continuous high-purity fatty acid glyceride production line, equipped with an industrial Internet platform, to achieve large-scale, digital, networked collaborative, intelligent and green production.

The application cases are rich and diverse. Cardlo's products have been widely applied in industries such as food, textiles, medicine, cosmetics, plastics, and industrial printing. They have successively passed international certifications such as FDA, FSSC, HALAL, and KOSHER, and have been exported to over 100 countries and regions around the world. We have established cooperative relationships with well-known enterprises such as Yantang Dairy and Ligao Food, and have been widely recognized by the market.

In all,if you need to purchase high-purity and environmentally friendly glycerol monooleate, or want to know about customized application solutions of this product in the fields of food, cosmetics, medicine, industry, etc., please feel free to contact us at any time! Whether it's questions about product specifications, production capacity guarantee, international certification or cooperation models, Cardlo will provide you with professional answers and efficient services. We look forward to working hand in hand with you to explore the market and achieve a win-win situation.

Previous Page

Related News

Tel: +86-20-3848 0078

Fax: +86-20-3848 0779

Email: info@gzcardlo.cn

Office: 7th Floor, North Tower, Ruihua Building, 267 Wushan Road, Tianhe District, Guangzhou City, Guangdong Province, China.

Factory: No.6 Huafeng Road, Yonghe District, Economic and Technological Development Zone, Guangzhou City, Guangdong Province, China.

©2023 Guangdong Cardlo Biotechnology Co., Ltd. All Rights Reserved